by Crossware

28. April 2014 09:39

The Crossware USB drivers for the FireFly and Jaguar debug interfaces are now signed and so fully compatible with Windows 8 and 8.1.

Our experiments with Windows 8.1 indicate that it does not display a 'Found New Hardware' message when a new USB device is inserted into the PC. In such cases it is necessary to open Device Manager to manual install the driver.

One approach is as follows:

To open Device Manager, press the Windows key to bring up the tiled desktop (if it is not already showing). Press <space> and type 'drivers'. In the search list that is displayed, select 'Update Device Drivers'. Device Manager should now open.

If you see 'Other Devices' listed in Device Manager, select it. You should then see the FireFly or Jaguar device listed. (If you don't see Other Devices, and you cannot see the entry for the FireFly or Jaguar device try unplugging and plugging the device back in to see which entry is removed and then added back into Device Manager.)

Right mouse click on the FireFly or Jaguar device entry and select 'Update Driver Software' Then select 'Browse my Computer for Driver Software'.

Now you can browse to and select the folder containing the appropriate Crossware signed driver. Follow the instructions to install the driver.

How can you tell if the Crossware driver is signed?

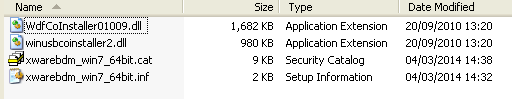

We do not actually sign the driver DLLs, these are signed by Microsoft. We sign the .INF file. The presence of a .CAT file matching the name of the .INF file indicates that the .INF file is signed. For the FireFly driver for 64-bit Windows you would see this:

by Crossware

18. September 2013 11:50

We have just released support for NXP ARM9 LPC29xx family of microcontrollers.

See this page for more details of this support:

www.crossware.com/Arm/Lcp29xx

049b1924-64d6-4117-b5df-a9e5d02cc107|0|.0

Tags: ARM9

Blog

by Crossware

26. April 2013 07:38

We do not have a Windows 7 PC which has a parallel port and so we have never been able to try a ColdFire parallel port BDM interface on this operating system. It was clear that parallel port debugging on the 64-bit version of Windows 7 was not going to be possible because our parallel port driver is a kernel driver and is not signed. As such, Windows 7 64-bit edition will not allow it to be installed under any circumstances.

Now we have information from one of our ColdFire customers who has recently migrated our ColdFire Suite to new PCs that use Windows 7 32-bit edition. They report that parallel port debugging with our ColdFire Suite and the P&E Micro parallel port BDM interface works successfully.

02bf12fb-bdd2-49bf-b8cc-a18e6561b71d|1|1.0

Tags:

Blog

by Crossware

3. May 2012 15:01

jState is our new Javascript simulator extension interface. With the V8 Javascript engine integrated into the environment, extending the Crossware Cortex-M3 simulator is fast and simple.

The STM32 Development Suite is the first package to incorporate jState and a new evaluation version is available: STM32 Development Suite Download.

For an introduction to jState see: jState Overview

For more details see: jState Documentation

by Crossware

2. April 2012 17:38

We have added additional options to our on-line shop.

Firstly it is now possible to select Royal Mail Airmail as a carrier option for international shipments. This delivery option takes longer (sometimes a lot longer - more than 4 weeks for Mexico!) but offers a cost saving over our traditional Fedex International Priority shipment method.

Secondly, we have added PayPal as a payment option so you can purchase items using your PayPal account. Initially, payments will be processed in pounds sterling. We will implement additional currencies when we become more familiar with the PayPal system.

by Crossware

20. March 2012 15:13

We have integrated Google's V8 Javascript engine into the Crossware environment and is now possible for the simulators to be extended using Javascript.

We've called this interface jState and the next version of Crossware Cortex-M3 simulator will support jState.

You can find more information on jState here: jState - Javascript Simulator Extension Interface

by Crossware

22. February 2012 09:09

We have recently been asked how to put the /Op option on the command line of the Crossware 8051 C Compiler when building from within the Embedded Development Studio IDE.

We do not recommend that the /Op option is applied from the command line. It can lead to unpredictable results and applying it across a whole module or a whole project can potentially lead to hard to track down faults.

Instead we recommend that it is applied to specific functions using the optimize pragma.

Here is the html version manual page for the /Op option:

http://www.crossware.com/smanuals/c8051/suppress.html

At the bottom of that page is a link to the page for the optimize pragma:

http://www.crossware.com/smanuals/c8051/optimize.html

So you would do something like this:

unsigned char a, b, c, d;

#pragma optimize("p", on)

func()

{

a = (b + c) / d;

}

#pragma optimize( "", on )

In this example, only the expressions in the function func() will have integral promotion suppressed.

Nevertheless, it is possible to apply command line options that are not specifically supported by the IDE by using the CCommandLine entry in a target.ini file. See this page:

http://www.crossware.com/smanuals/estudio/_t117.html

by Crossware

15. February 2012 17:40

The Crossware web and mail servers went offline on Friday due to a failure of our Internet connection. We relocated the servers when it was clear that the issue would take some time to solve and the servers were operational in their new location by Monday afternoon.

The Internet connection fault is now fixed and everything should now be back to normal.

7f7acdc0-3767-4328-88c8-7907961a574c|0|.0

Tags:

Blog

by Crossware

14. December 2011 17:40

Our STM32 Development Suite is proving to be very popular and to help new users get started we have prepared a brief tutorial.

You can access the tutorial using this link:

http://www.crossware.com/stm32/firststeps/index.html

by Crossware

25. October 2011 10:36

A question we have just been asked is "How to see the output of the ARM LPC2103 on Crossware?".

We will assume that the user is interested in outputting messages from the excecuting ARM chip.

Here is a simple method of doing that.

Create a new project selecting the NXP LPC2103 as the target chip, accepting all defaults offered by the New Project Wizard.

Add:

printf("Hello world\n");

to main(). For example:

main()

{

printf("Hello world\n");

while (1)

{

}

}

Use the Headers Wizard to add the include file stdio.h to the xstdsys.h. (Or manually add #include <stdio.h> to just above main().)

Build the project.

Run the program in the simulator and the Hello world message will appear in the Debug view.

Run the program on the hardware using the Jaguar USB debugger interface and the Hello world message will also appear in the Debug view.

How does this work?

The ARM7 debug communication channel (DCC) is being used to route the message to the Debug view. A special putch() routine in the library sends the output to the DCC. When you add printf() to your program, putch() is required as the output function. If you do not include your own version of putch() in your program then this special library version will be automatically included. When debugging with Jaguar, Jaguar captures the output from the DCC and the debugger writes it to the Debug view. When simulating, the DCC is simulated and so the output is captured and written to the debug view in a similar way.

This use of the DCC is often referred to as 'semi-hosting'. For more information on semi-hosting see the ARM Simulator and Debugger User Guide via the Books view or refer to this and following pages of the online version of the guide:

http://www.crossware.com/smanuals/sdarm/semi_overview.html

44e4c98f-278e-40fc-bd15-ab73ef3f51c1|1|5.0

Tags:

Blog